Collapsible Aluminum Tubes

They’re the preferred packaging format for pharmaceutical products like ointments and creams, which requires high barrier properties for product stability over a long shelf-life. Aluminium Tubes are widely used all over the world for the packaging of pharmaceutical, hair-care, industrial and food products such as Ketchup, Mustard, Mayonnaise, Caviar paste, Salmon paste, Cheese, etc.

A great advantage of collapsible Aluminium Tubes is that they can keep out germs and protect the temperature of the product. Tubes also prevent moisture from affecting the product as it is not permeable and does not expand back after use, which does not let air back inside the tube which can cause contamination.

In the world of Aluminum tubes, one can be certain that the future lies within this industry.

Benefits of Collapsible Tubes

Beyond reasonable doubt Aluminum tubes makes it as one of the most convenient packaging means to so many products, and here is why…

Sustainable

It has long shelf life and can with stand high temperatures.

Tamper Proof

Makes tampering impossible and it cannot be re-filled or re-used

Protective

The Contents in the package remains protected by the use of membranes and latex on the end of the tube that makes it free from contamination

Stylish

The attractive Possess along with the bright surface will also lend themselves makes the trouble-free printing so it will enhance customer appeal.

Hygienic

The collapsible tubes are hygienic, Impart no taste, non-absorbent, flavor, odor or to contents. Unlike the laminate, Al tubes are hygienic because it doesn’t allow air suck-back in the tube when squeezed so it prevents contamination.

Lightweight

Easier for handling and reduces the transportation handling cost.

Recyclable

The slug composition we use are made of 99.87% Aluminum and therefore the tube can be 100% recyclable. This is why Aluminum tubes are environmentally friendly.

![]()

Protective

The Contents in the package remains protected by the use of membranes and latex on the end of the tube that makes it free from contamination

![]()

Sustainable

It has long shelf life and can with stand high temperatures.

![]()

Tamper Proof

Makes tampering impossible and it cannot be re-filled or re-used

![]()

Lightweight

Easier for handling and reduces the transportation handling cost

![]()

Stylish

The attractive Possess along with the bright surface will also lend themselves makes the trouble-free printing so it will enhance customer appeal

![]()

Recyclable

The slug composition we use are made of 99.87% Aluminum and therefore the tube can be 100% recyclable. This is why Aluminum tubes are environmentally friendly.

![]()

Hygienic

The collapsible tubes are hygienic, Impart no taste, non-absorbent, flavor, odor or to contents. Unlike the laminate, Al tubes are hygienic because it doesn’t allow air suck-back in the tube when squeezed so it prevents contamination.

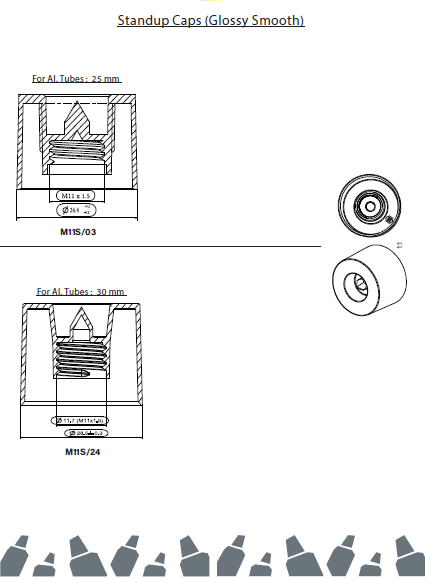

Producing our own plastic caps to offer a range of options

Featuring many sizes, our plastic cap production is made to suit your tube dimensions and is produced in-house to ensure that your product is secured and in tune with the aluminum tube.

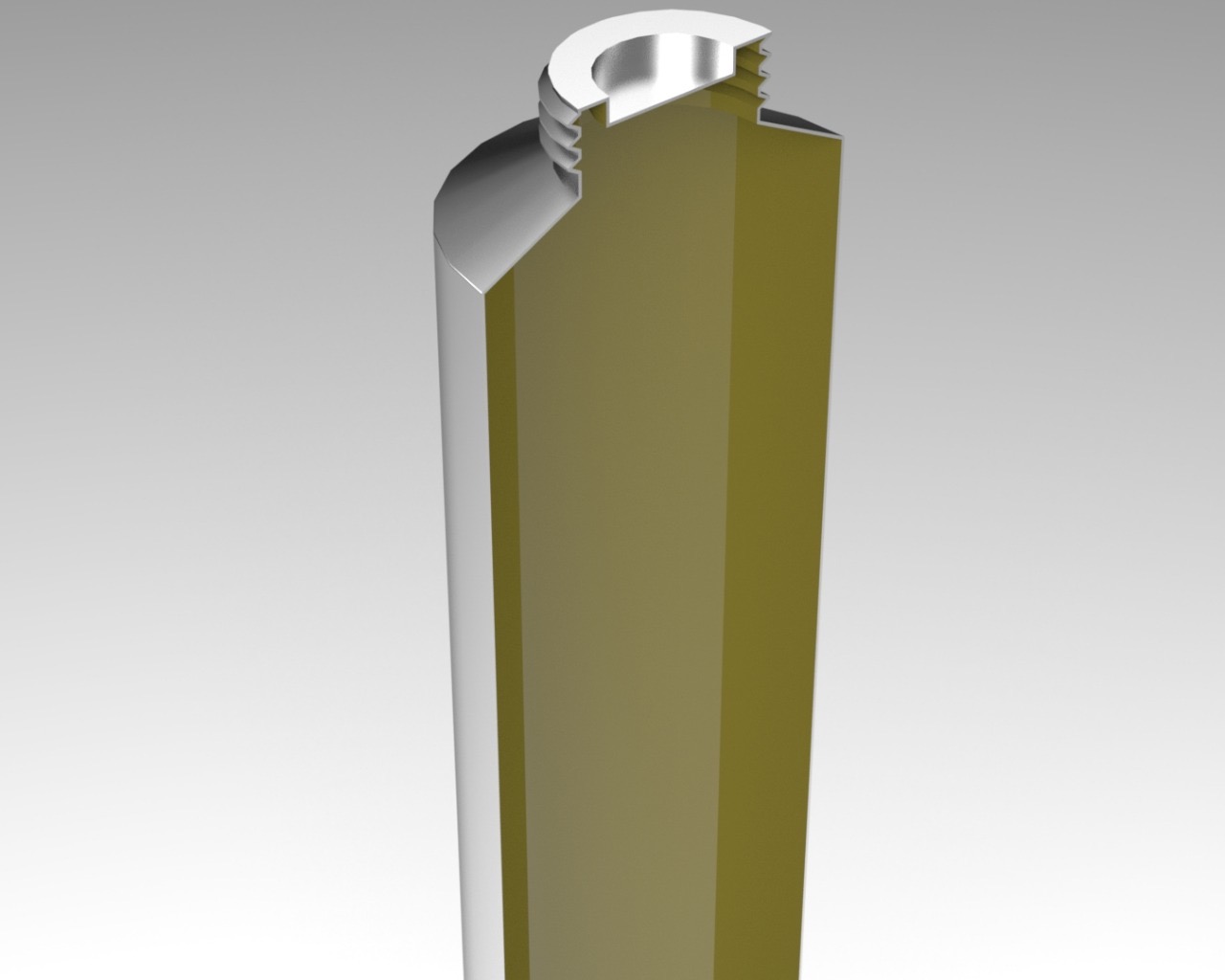

Illustrative way to visualise the evolution of a tube

The tube goes through a lengthy process to become a final product. It goes through about more than 13 stages to become a finished product. In this segment, we illustrate how the tube evolves from being a slug into a fillable tube

This is how the raw material Aluminum is acquired from our suppliers as a slug

It goes through a backward extrusion process to take the shape of an open-ended tube

It goes through a backward extrusion process to take the shape of an open-ended tube

Then it goes through a trimming process where the tube is cut to length from the open end. In the same process, the thread is created from the top part for the cap to be applied later on.

High Solids interior lacquer for collapsible aluminum tubes’ protection. The exclusive formulation, based on a high molecular weight epoxy-phenolic resin and fully etherified amino resin combination being cross-linked via an innovative hardener, yields a film showing an extremely high resistance to many products, ranging from alkaline (such as hair dyes) to acidic (such as foods like tomato sauce). The high solids content provides films which are free of micro-porosity and sagging defects even at high thickness

High Solids interior lacquer for collapsible aluminum tubes’ protection. The exclusive formulation, based on a high molecular weight epoxy-phenolic resin and fully etherified amino resin combination being cross-linked via an innovative hardener, yields a film showing an extremely high resistance to many products, ranging from alkaline (such as hair dyes) to acidic (such as foods like tomato sauce). The high solids content provides films which are free of micro-porosity and sagging defects even at high thickness

White polyester based enamel for external protection of collapsible tubes with excellent application properties and excellent cold-crush resistance down to a temperature of around-20°C, it’s easily overprinted with inks. Having very good chemical resistance to both acidic and alkaline products, along with several solvents, can be suitable for many kinds of filling products.

Sealing Compound was especially developed for sealing flexible aluminum tubes. It is suitable for hot and cold filling of vegetable products, milk and its byproducts, toothpastes, pastes in general, shaving cream, hair dye, fatty products, pharmaceutical and medical products. The sealant is applied by spraying with rotating nozzle. The typical film thickness is around 50 -60 μm

Sealing Compound was especially developed for sealing flexible aluminum tubes. It is suitable for hot and cold filling of vegetable products, milk and its byproducts, toothpastes, pastes in general, shaving cream, hair dye, fatty products, pharmaceutical and medical products. The sealant is applied by spraying with rotating nozzle. The typical film thickness is around 50 -60 μm